OUR FLEET

Stena Drilling is one of the world’s foremost independent drilling contractors, a wholly-owned subsidiary of Stena AB.

Our fleet consists of two semi-submersible units and five MPD Capable Ultra Deep Water DP3 drillships. Scroll down to find out more!

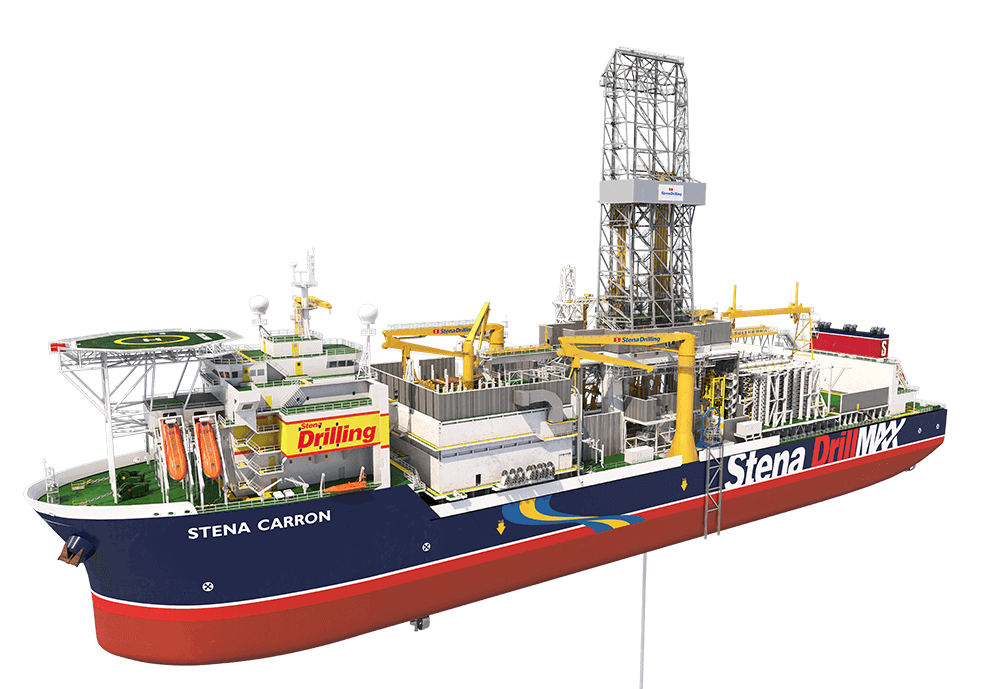

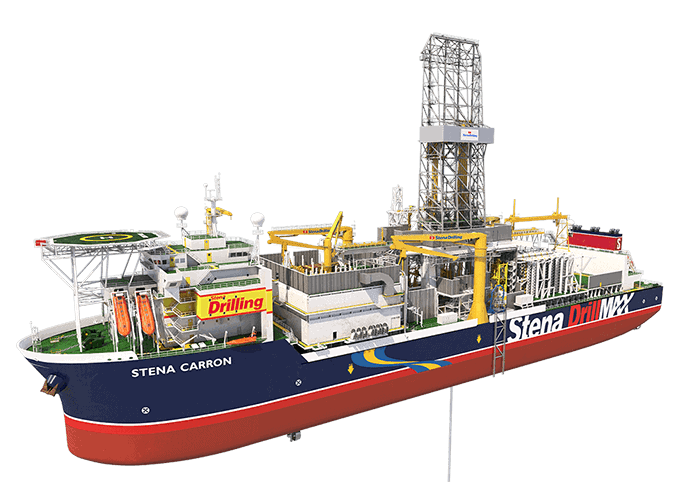

The Stena Carron is a Harsh Environment dynamically positioned DP Class 3 drillship capable of drilling in water depths up to 10,000ft.

The Stena Carron is a Harsh Environment dynamically positioned DP Class 3 drillship capable of drilling in water depths up to 10,000ft.

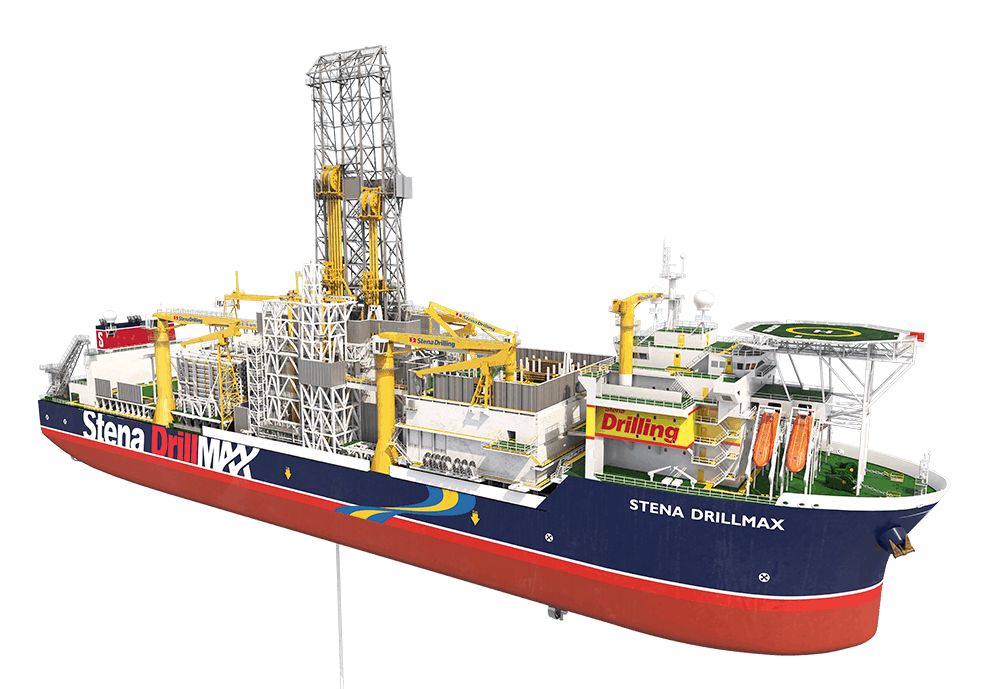

The Stena DrillMAX is a Harsh Environment dynamically positioned DP Class 3 drillship capable of drilling in water depths up to 10,000ft.

The Stena DrillMAX is a Harsh Environment dynamically positioned DP Class 3 drillship capable of drilling in water depths up to 10,000ft.

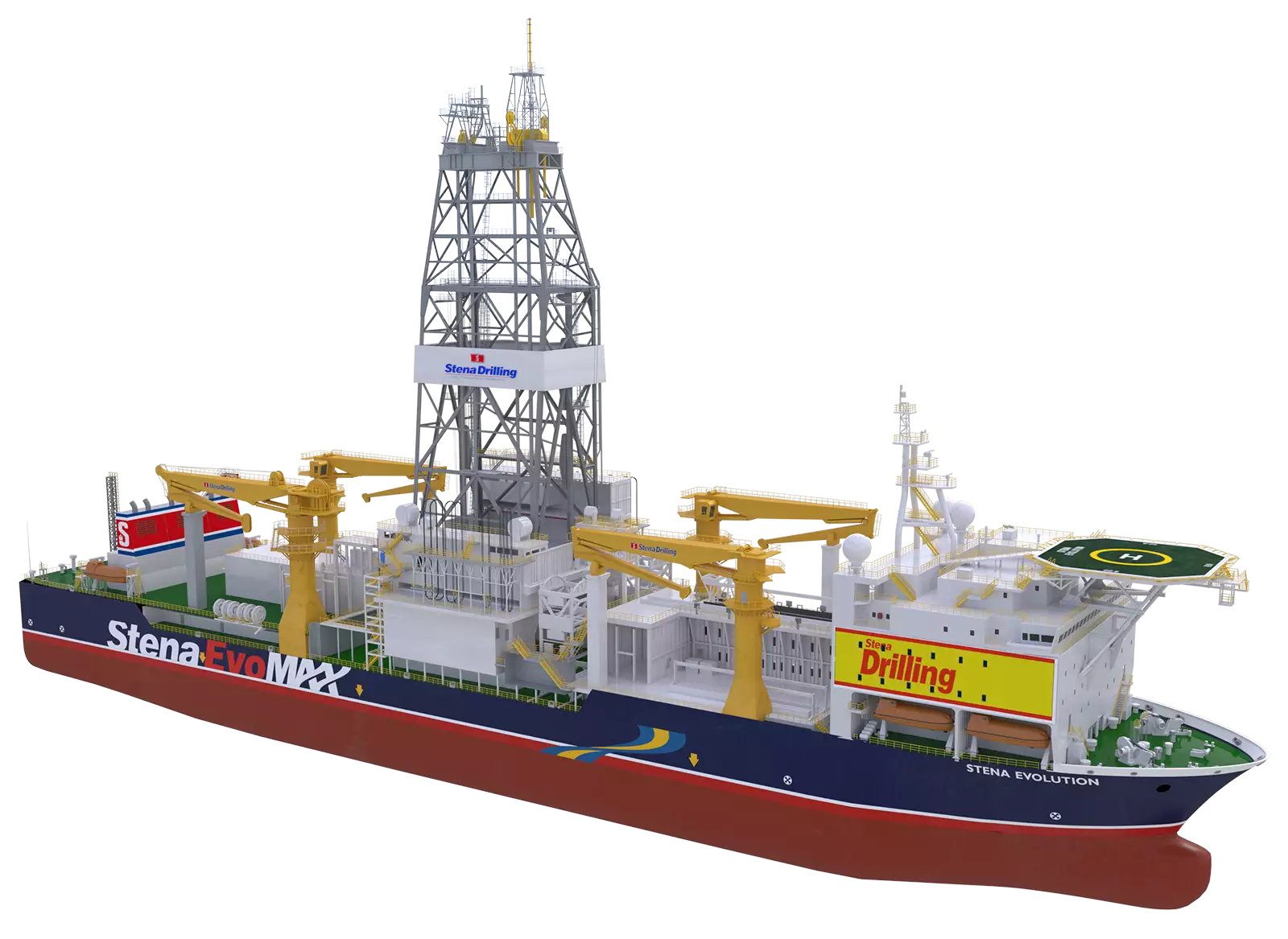

The Stena Evolution will be one of the most advanced Ultra Deep Water Drillships on the market when delivered Q4 2023. The 7th Generation Ultra Deepwater DP3 Drillship is capable of drilling in water depths of 12,000ft and drilling depths up to 40,000ft.

The Stena Evolution will be one of the most advanced Ultra Deep Water Drillships on the market when delivered Q4 2023 The 7th Generation Ultra Deepwater DP3 Drillship is capable of drilling in water depths of 12,000ft and drilling depths up to 40,000ft.

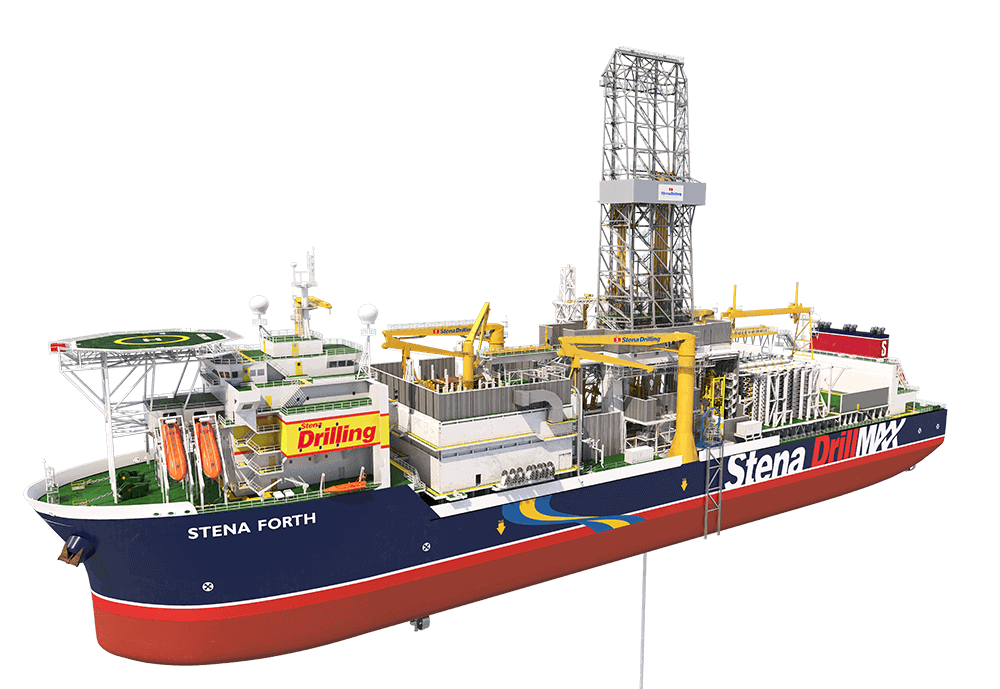

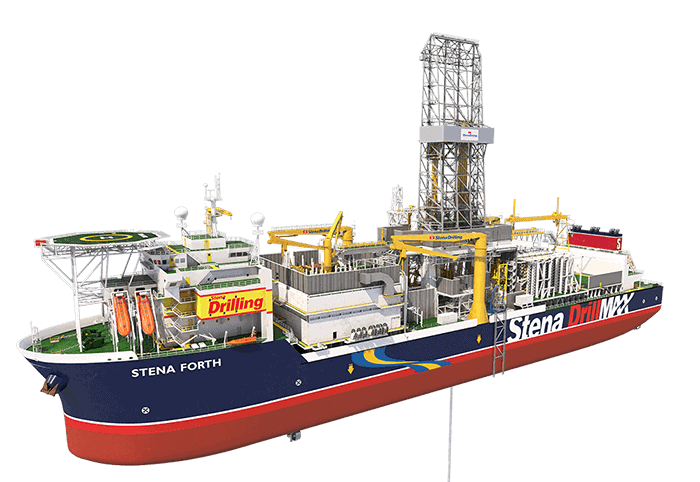

Stena Forth is a harsh environment, dynamically positioned DP Class 3 drillship capable of drilling in water depths up to 10,000’.

Stena Forth is a harsh environment, dynamically positioned DP Class 3 drillship capable of drilling in water depths up to 10,000’.

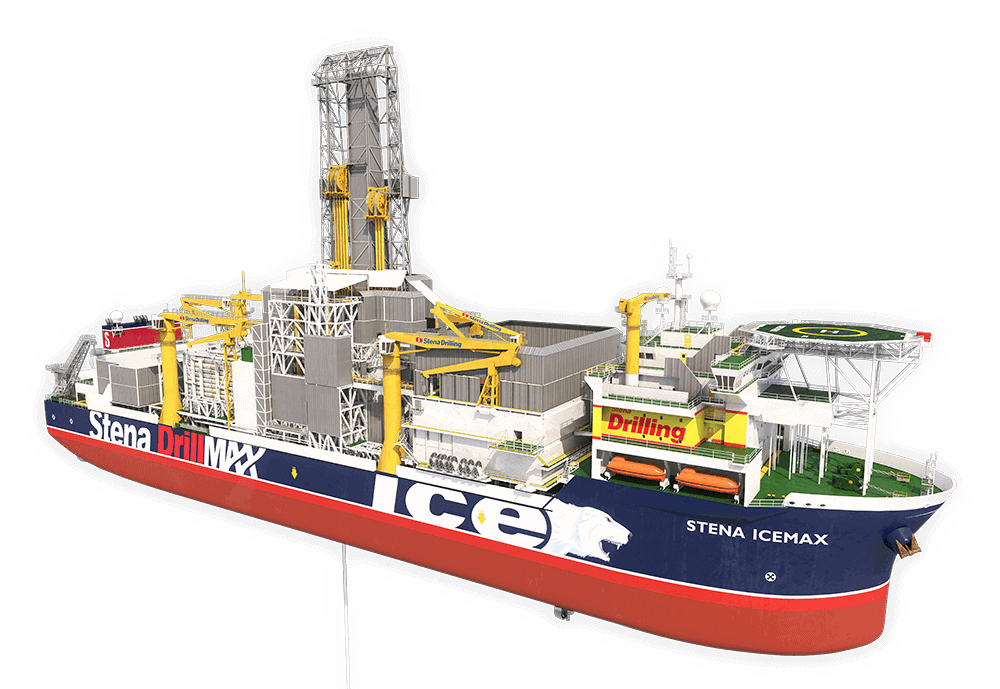

Stena IceMAX is the world’s first dynamically positioned, dual mast ice-class drillship. Capable of drilling in water depths up to 10, 000ft, the Stena IceMAX is a Harsh Environment DP Class 3 drillship.

Stena IceMAX is the world’s first dynamically positioned, dual mast ice-class drillship. Capable of drilling in water depths up to 10, 000ft, the Stena IceMAX is a Harsh Environment DP Class 3 drillship.

The Stena Don is a harsh environment dynamically positioned Class 3 semi submersible drilling, completion and workover vessel for worldwide operations with mooring capability.

The Stena Don is a harsh environment dynamically positioned Class 3 semi submersible drilling, completion and workover vessel for worldwide operations with mooring capability.

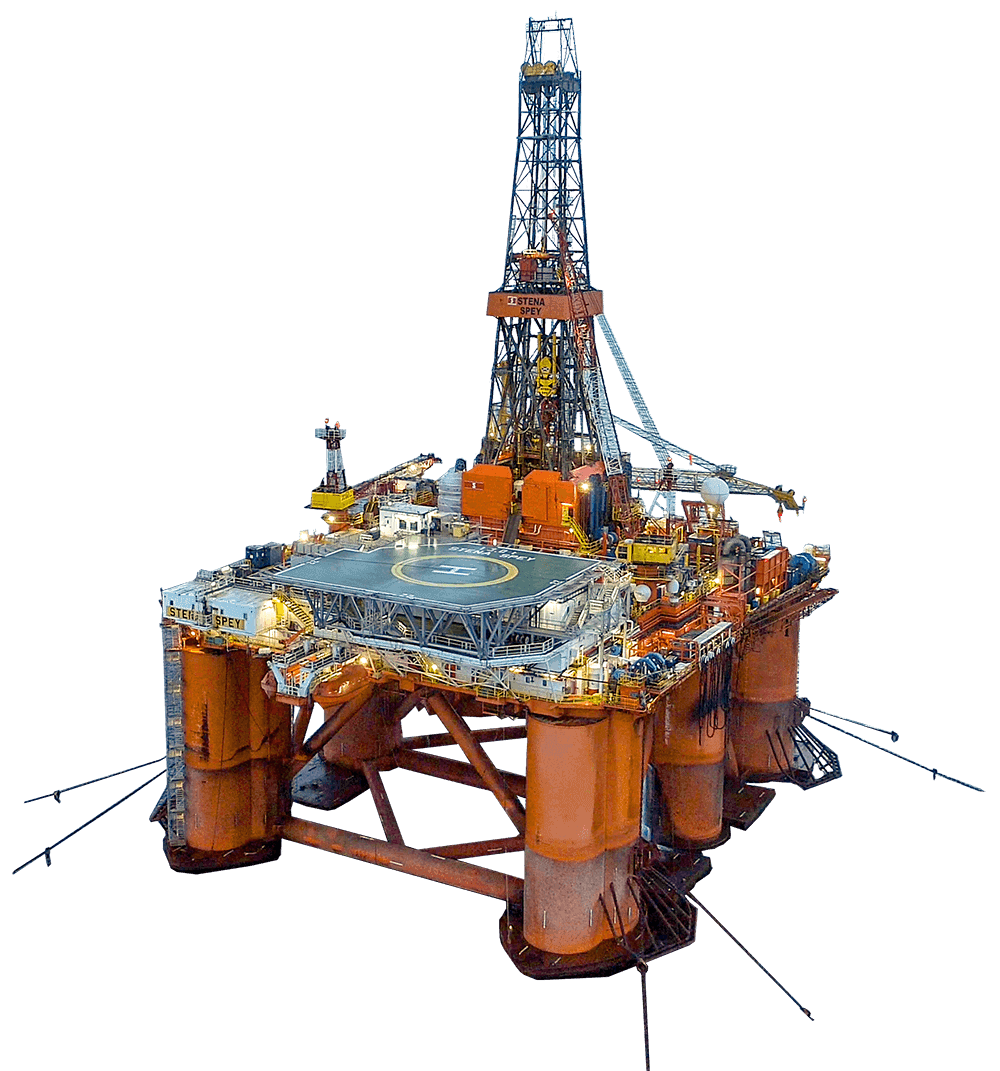

The Stena Spey is a Friede & Goldman L907 (enhanced Pacesetter) twin pontoon, column stabilised self propelled, semi submersible offshore drilling unit.

The Stena Spey is a Friede & Goldman L907 (enhanced Pacesetter) twin pontoon, column stabilised self propelled, semi submersible offshore drilling unit.